Rotary vane dry vacuum pump

Classification:

Keywords:

E-mail:

Product details:

Principle and Characteristics:

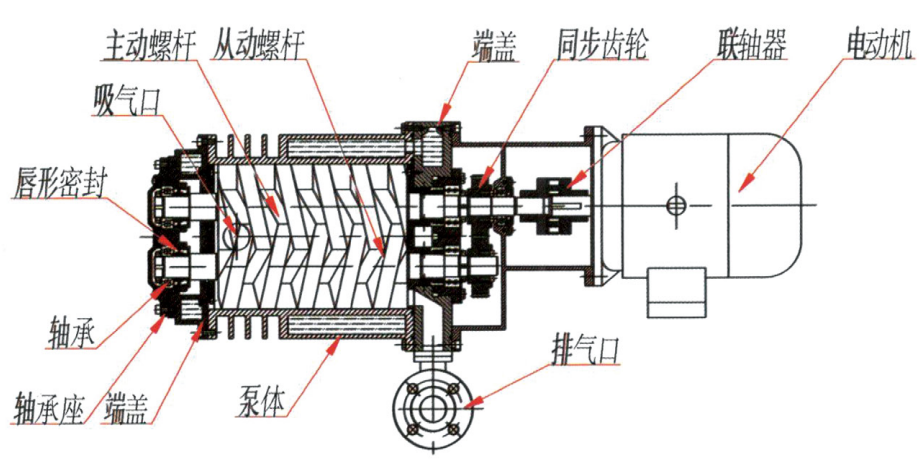

A dry screw vacuum pump achieves high vacuum by using a pair of counter-rotating screws in the pump chamber to draw in, compress, and exhaust gas. Two counter-rotating, non-contacting screw rotors rotate at the same speed within the pump chamber. As the screws rotate, a certain volume of gas is drawn in at the pump inlet, compressed, and then exhausted from the outlet. Because there is no contact between the two screws or between the screws and the pump chamber, no lubricating oil is needed in the pump chamber. Lubricating oil for the gears and shaft seals is sealed from the pump chamber via the shaft seals. The pump can be cooled by direct circulation of cooling water or by a cooling device with a fan and radiator. The dry screw vacuum pump uses specially designed screw rotor profiles, which, compared to ordinary screw pumps, reduce energy consumption by about 30%, reduce exhaust temperature rise by about 100℃, and significantly improve the reliability and stability of the product's operation, making it suitable for vacuum needs in any working condition. It can be widely used in solvent recovery, vacuum drying, concentration, crystallization, and distillation processes in the chemical and pharmaceutical industries; vacuum extrusion molding in the plastics and rubber industries; vacuum degassing in the metallurgical industry; vacuum degassing and drying in the solar energy, microelectronics, and lithium battery industries, etc.

Main Features:

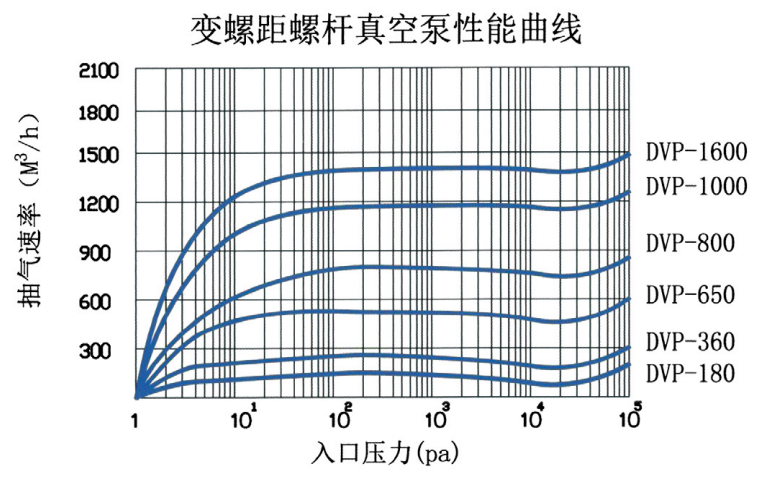

1. The screw rotor adopts a variable pitch structure design, with an ultimate vacuum of less than 1 Pa, capable of meeting various vacuum processing needs from atmospheric pressure to high vacuum;

2. Oil-free pump chamber allows for reliable use in various special working conditions;

3. Capable of long-term reliable operation from atmospheric pressure to a few Pascals;

4. No friction between moving parts, simple structure, lower operation, use and maintenance costs;

5. Uses nitrogen gas and lip-type composite seals, ensuring high reliability, low operating costs, and simple maintenance;

6. Rotors are high-speed dynamically balanced, using flange-connected motors, resulting in high concentricity, low vibration, and low noise;

7. The flow section uses a Hastelloy corrosion-resistant coating, making condensation less likely to occur in the pump chamber, improving corrosion resistance;

8. Compared to oil-sealed pumps, liquid ring pumps, and oil-sealed pumps, there is no exhaust gas, waste liquid, or waste oil discharge, resulting in energy-efficient and environmentally friendly operation.

It can be used independently or combined with Roots vacuum pumps, air-cooled Roots vacuum pumps, molecular vacuum pumps, etc., to form oil-free high-vacuum obtaining equipment.

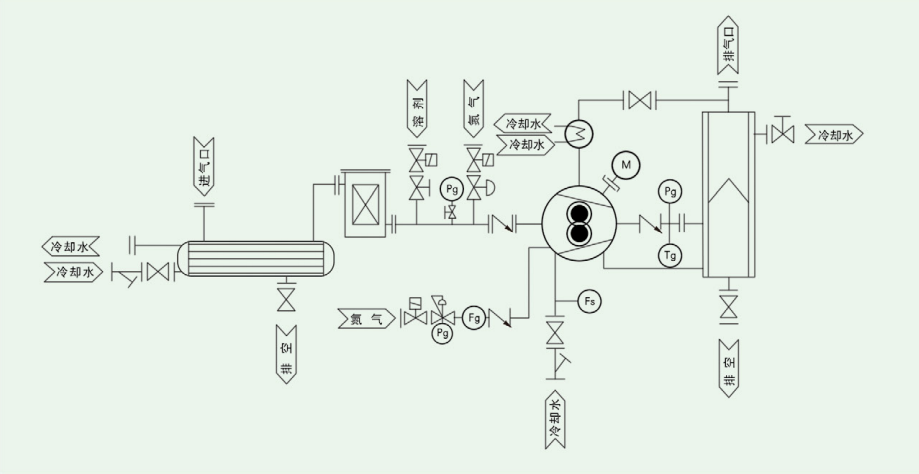

Flowchart:

Main Materials:

Pump body and end cover: High-strength cast iron;

Corrosion-resistant coating: Hastelloy;

Lip seal: Imported polytetrafluoroethylene mixture;

Screw rotor: Ductile iron;

Synchronous gear: Alloy steel;

Shaft seal: High-temperature fluororubber;

Sealing bushing: Stainless steel surface with ceramic coating

Standard Configuration:

Base, pump head, coupling, motor, start-up filter, intake connector, check valve, vacuum gauge, manual inflation valve exhaust muffler:

Optional Accessories:

Intake filter, intake condenser, solvent washing device, nitrogen purge device, nitrogen sealing device, exhaust condenser, electromagnetic inflation valve, cooling water flow switch, temperature sensor, pressure transducer;

Typical Applications:

| Industrial furnace | Chemical, pharmaceutical | Vacuum coating | Metallurgy | Leak detection |

| Packaging and printing | Drying process | Exhaust gas recovery | Lithium batteries | Solar energy |

| Power industry | Microelectronics industry | Wind tunnel testing |

Specifications:

Variable pitch screw vacuum pump specifications

Note: The cooling water volume for the dry screw vacuum pump provided in the table is for 20℃ normal temperature water. When a rear-mounted cooling device is used, the cooling water volume will increase. The inlet and outlet water temperature difference should generally be controlled below 7℃.

Performance Curve:

Leave A Message