Gas circulation cooling Roots vacuum pump

Classification:

Keywords:

E-mail:

Product details:

Structural Principle:

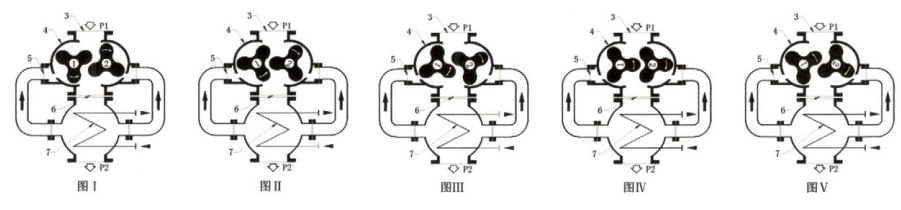

Gas-cooled rotary vane vacuum pumps, also known as gas-cooled Roots pumps, mainly consist of rotor 1, rotor 2, pump body 4, cooler 7, etc. Due to their special internal structural design, they can operate reliably for extended periods under high pressure differences and high compression ratios. Cooling gas enters the pump's suction chamber from both sides of the pump body, preventing overheating due to gas compression without affecting the pump's pumping performance. Figures 1 to V show the rotors rotating 120 degrees in the pump chamber, completing a single suction and exhaust process. The cooler and motor are essential accessories for each pump, with specifications determined by different operating conditions. Pumps can be used individually, multiple units can be connected in series, or they can be connected in series with liquid ring vacuum pumps and ordinary Roots vacuum pumps to achieve higher vacuum degrees to meet various process requirements.

Main Features:

1. When used individually and directly exhausting to the atmosphere, the working vacuum can reach 150mbar. 2. Multi-stage series connection or series connection with other fore-vacuum pumps can achieve a medium vacuum range. 3. Special structural design ensures that the pump does not overheat or overload during operation under high pressure differences and high compression ratios. 4. Three-lobe involute structure and high-precision machining ensure smooth and quiet operation. 5. The main performance indicators such as pumping performance, noise, and vibration are significantly improved compared to traditional two-lobe pumps. 6. Advanced balanced mechanical seals make the pump's sealing performance more reliable than traditional skeleton seals. 7. The pump chamber is oil-free and suitable for evacuating general air and various special gases. 8. Compared with other mechanical vacuum pumps, the energy-saving effect is very significant.

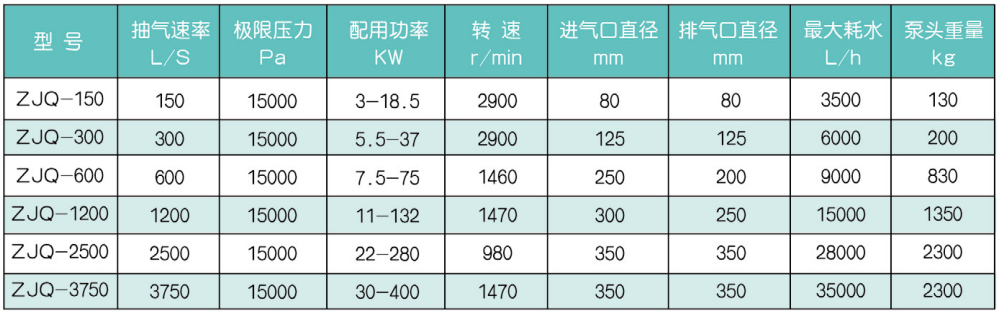

Specifications:

Previous

Previous

Leave A Message