ZJ Series Roots Vacuum Pump

Classification:

Keywords:

Zhuocheng Pump

zhuocheng

E-mail:

Product details:

Overview:

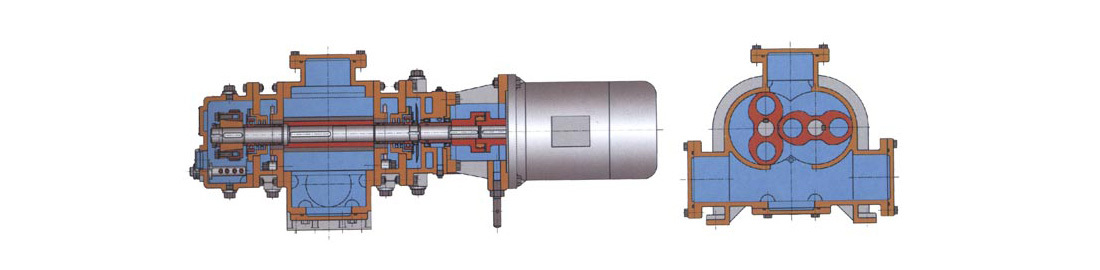

ZJ series Roots vacuum pump is a positive displacement vacuum pump, also known as mechanical booster pump. It is one of the main pumping equipment for medium and high vacuum at present. Its working principle is similar to that of Roots blower. It uses two 8-shaped turns to rotate synchronously in the pump shell to complete suction and exhaust.

In view of the process of removing a large amount of water vapor and solvent in chemical, pharmaceutical and other industries, our company has improved the sealing structure of the pump chamber and bearing chamber of ZJ series Roots vacuum pump, greatly reducing the oil emulsification phenomenon of bearing chamber and gear chamber, making ZJ series Roots vacuum pump more suitable for pumping a large amount of water vapor and solvent with water ring vacuum pump.

Key features:

♦There is a large pumping speed in the limited wide pressure range (1 ~ 1xl04Pa).

♦The pump chamber is oil-free, avoiding oil vapor contamination of the vacuum system.

♦Small vibration, low noise.

♦Mechanical friction loss is small, so the driving power is small.

♦Easy to maintain and repair, low cost and high life.

♦Condensable gas can be pumped out.

♦It cannot be used alone and must be equipped with a front pump. It is not allowed to start under atmospheric pressure. It can only be started when the front pump draws the inlet pressure of Roots pump to the allowable inlet pressure. The front pump is generally a water ring vacuum pump, an oil ring vacuum pump, and an oil-sealed mechanical pump.

♦In view of the characteristics of removing water vapor and organic solvent, the emulsification problem of bearing cavity pump oil was solved.

Roots vacuum pump main technical performance specifications:

|

Model |

ZJ-15 |

ZJ-30 |

ZJ-70 |

ZJ-150 |

ZJ-300 |

ZJ-600 |

ZJ-1200 |

ZJ-2500 |

|

|

Pumping speed (L/S) |

15 |

30 |

70 |

150 |

300 |

600 |

1200 |

2500 |

|

|

Ultimate pressure (Pa) |

5 x 10-2 |

5 x 10-2 |

5 x 10-2 |

5 x 10-2 |

5 x 10~2 |

5 x 10-2 |

5x10-2 |

5X10'2 |

|

|

Maximum charging pressure difference (Pa) |

8000 |

8000 |

8000 |

6000 |

4500 |

4500 |

3000 |

3000 |

|

|

Rotation speed (r/min) |

1390 |

2770 |

2870 |

2970 |

1450 |

2900 |

1450 |

2900 |

|

|

□ Diameter (mm) |

Imports |

50 |

50 |

80 |

100 |

150 |

150 |

300 |

300 |

|

Export |

40 |

40 |

50 |

100 |

150 |

150 |

300 |

300 |

|

|

Weight (Kg) |

70 |

70 |

100 |

215 |

480 |

503 |

1580 |

1640 |

|

|

Motor power (KW) |

0.55 |

0.75 |

1.5 |

3 |

4 |

5.5 |

11 |

22 |

|

Note: The limit pressure value listed in the above table is the limit pressure measured when the Roots vacuum pump is equipped with rotary vane vacuum pump or slide valve vacuum pump with appropriate pumping rate as the front pump. If water ring vacuum pump and oil ring vacuum pump are used as the front pump, the limit pressure will be higher than this value. Please refer to Roots Liquid Ring Vacuum Unit for specific parameters.

Next

Next

Leave A Message