ZF series vacuum pump station

Classification:

Keywords:

E-mail:

Product details:

ZF series vacuum pump station

Overview:

ZF series vacuum pump station (also known as vacuum generator, vacuum negative pressure station, etc.) is a complete system with one or two water ring vacuum pumps as vacuum acquisition equipment and vacuum tanks as vacuum storage equipment. When the vacuum source is frequently used and the required pumping capacity is not too large, the system greatly saves energy compared with the direct use of the vacuum pump, and effectively improves the service life of the vacuum pump.

The equipment can provide vacuum source of medical gas center station for various large and medium-sized hospitals in China, and is widely used in vacuum station of chemical industry and pharmaceutical industry, canning system of light industry, negative pressure forming of rubber and plastic engineering parts of automobile industry, impregnation of flame retardant conveyor belt used in coal mine and vacuum source of casting industry (V method, VRH, V-EPC), etc.

Working principle:

1. Two vacuum pumps

First, set the upper and lower limit values of the vacuum system (for example, the upper limit value is set to -0.08MPa and the lower limit value is set to -0.06MPa). After starting the system, one of the vacuum pumps starts to work until the vacuum degree in the vacuum tank is higher than the upper limit value -0.08MPa. At this time, the vacuum pump automatically stops running, and the vacuum in the vacuum tank is automatically cut off by the vacuum check valve, until the vacuum degree in the vacuum tank reaches the upper limit value of-0.08MPa, the automatic operation shall be repeated in this cycle to keep the vacuum degree in the vacuum tank between the upper limit value and the lower limit value. If the vacuum degree in the vacuum tank is lower than the lower limit for more than a certain period of time due to the large gas demand, and a single vacuum pump cannot pump the vacuum degree in the tank above the lower limit, another vacuum pump will automatically start until the upper limit is exceeded.

The two vacuum pumps can also be switched to manual start and stop.

2. One vacuum pump

First, set the upper and lower limits of the vacuum system (for example, the upper limit is set to -0.08MPa, and the lower limit is set to -0.06MPa). After starting the system, the vacuum pump will automatically stop when the vacuum pump reaches the upper limit, and the system will automatically start when the vacuum degree is lower than the lower limit. The vacuum pump can also be started and stopped manually.

Features:

Since the first start of the device, the whole operation process can be fully automatic control. During its working process, the vacuum degree in the vacuum system fluctuates up and down within its allowable range, and its fluctuation range can be adjusted according to user requirements.

The device automatically controls the system under the condition of unmanned operation, and can automatically close the vacuum system when the power is cut off.

The device is equipped with a steam separator, which can save water and reduce environmental pollution.

The vacuum tank of the device can be designed as horizontal and vertical structure according to the site, and the installation is more flexible.

ZF series vacuum pump station performance parameters:

| Vacuum tank volume m3 | Model of vacuum pump station | Recommended vacuum pump (water ring vacuum pump) | Power KW | Vacuum degree fluctuation range MPa | Ultimate vacuum degree MPa | Inner diameter of working interface mm |

| 0.3 | ZF-0.3A | 2BV2060 x 2 sets | 1.1KWx2 | 40 | ||

| ZF-0.3B | 2BV2061 x 2 sets | 1.5KWx2 | ||||

| 0.5 | ZF-0.5A | 2BV2061 x 2 sets | 1.5KWx2 | 50 | ||

| ZF-0.5B | 2BV2070 x 2 sets | 3KWx2 | ||||

| ZF-1A | 2BV2061 x 2 sets | 1.5KWx2 | ||||

| 1 | ZF-1B | 2BV2070 x 2 sets | 3KWx2 | 80 | ||

| ZF-1C | 2BV5110x2 units | 4KWx2 | ||||

| ZF-1.5A | 2BV5110x2 units | 4KWx2 | ||||

| 1.5 | ZF-1.5B | 2BV5111 x2 units | 5.5KWx2 | 80 | ||

| ZF-1.5C | 2BV5121 x2 units | 7.5KWx2 | 0 to-0.09 | -0.098 | ||

| ZF-2A | 2BV5111 x2 units | 5.5KWx2 | ||||

| 2 | ZF-2B | 2BV5121 x2 units | 7.5KWx2 | 100 | ||

| ZF-2C | 2BV5131 x2 units | 11KWx2 | ||||

| ZF-3A | 2BV5121 x2 units | 7.5KWx2 | ||||

| 3 | ZF-3B | 2BV5131 x2 units | 11KWx2 | 100 | ||

| ZF-3C | 2BV5161 x2 units | 15KWx2 | ||||

| ZF-5A | 2BV5131 x2 units | 11KWx2 | ||||

| 5 | ZF-5B | 2BV5161 x2 units | 15KWx2 | 150 | ||

| ZF-5C | 2BV5161 x3 sets | 15KW x 3 |

Note: 1. The above models of vacuum pump are recommended products, and the vacuum pump model with appropriate pumping speed can also be selected according to the actual situation.

2. The above models are our company's standard series of products, and can also be customized as special-shaped vacuum tanks, optional vacuum pumps, customized interface flange sizes, etc. according to users' requirements.

3. The vacuum tank can be designed as horizontal and vertical structure according to the needs of users on site, please indicate when ordering.

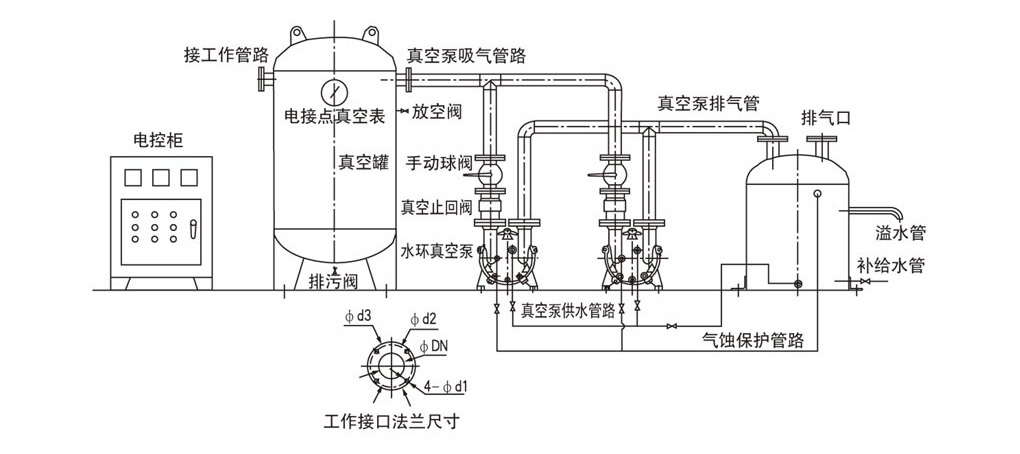

Schematic Diagram of ZF Series Vacuum Pump Station

Leave A Message