2BW series water (liquid) ring vacuum pump/compressor closed circuit circulation system

Classification:

Keywords:

Zhuocheng Pump

zhuocheng

E-mail:

Product details:

Overview

Water ring vacuum pump because of its working principle and structural characteristics in the chemical, pharmaceutical and other industries to a wide range of applications.

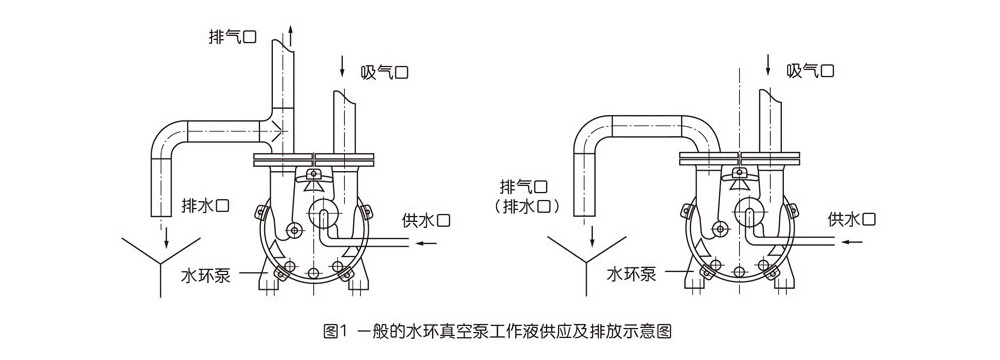

In normal applications, the working fluid of the water ring vacuum pump is mostly in a straight-line manner, as shown in Figure 1:

♦The water discharged from the water ring vacuum pump enters a large circulating pool or is directly discharged.

This water supply and drainage method is convenient to connect, simple to use, and is widely used in practical applications.

♦However, if the extracted medium contains organic solvents, toxic substances, etc., the use method shown in Figure I has the following disadvantages:

1, because of the water ring pump in the pumping gas, the pumping gas and working fluid mixed, drainage □ discharge of water will contain some organic solvents, toxic substances, due to the large amount of water emissions, water emissions on environmental protection caused a lot of pressure.

Water containing organic solvents and toxic substances will release harmful gases and increase environmental pollution.

The extracted organic solvent is not easy to recover and is wasted.

♦In view of the above problems, more and more chemical and pharmaceutical companies have adopted water ring vacuum pump closed-circuit circulation system.

The main features of the closed-circuit system of the water-damaged vacuum pump are as follows:

1. The unit is supplied as a complete set of equipment, including gas-liquid separator, heat exchanger, rack, internal pipeline and other accessories, which is more conducive to the installation of users and can greatly shorten the installation cycle of users.

2. The working fluid can be recycled with water or various chemical solvents, which greatly reduces the environmental pollution of the chemical industry.

3. If the extracted medium is used as the working fluid, the extracted medium can be recovered.

4, 2BW series closed-loop system needs to be designed according to the user's inlet conditions, cooling water conditions, exhaust conditions, etc., is a non-standard product.

Working principle:

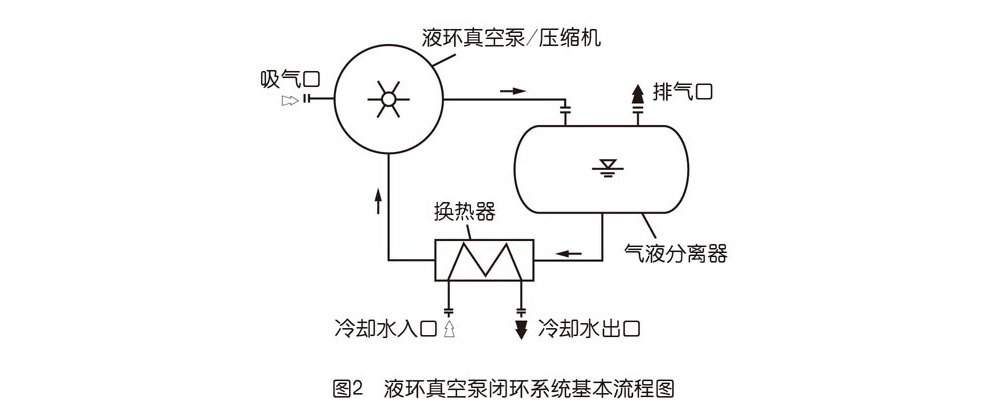

The most basic 2BW series liquid ring vacuum pump/compressor closed-circuit circulation system is shown in Figure 2:

The pumped gas enters the liquid ring vacuum pump/compressor from the suction port, and enters the gas-liquid separator together with part of the working fluid after being compressed by the liquid ring vacuum pump/compressor. The gas-liquid two-phase is separated in the gas-liquid separator. The gas is discharged from the exhaust port, and the working fluid is sucked by the liquid ring pump/compressor through the heat exchanger for recycling.

The liquid ring pump will generate heat during the working process. The main heat includes: the ineffective power of the vacuum pump/compressor; the heat caused by the high temperature of the suction gas; the suction gas contains condensable gas and releases phase change heat during the compression process. The main function of the heat exchanger is to cool the working fluid through cooling water to keep the temperature of the working fluid within a reasonable range.

Equipment composition: liquid ring vacuum pump/compressor closed circuit system main components include:

♦Liquid ring vacuum pump/compressor

♦Gas-liquid separator

♦Heat Exchanger

♦Shared Chassis

♦Internal pipeline

In use, the following accessories can be installed according to the actual situation:

1. Suction port vacuum check valve. In order to prevent backflow when the vacuum pump/compressor is stopped, it is generally necessary to install a vacuum check valve or pneumatic valve at the inlet of the pump.

2. Suction port vacuum gauge or pressure sensor. In order to facilitate the observation of pump suction port pressure, can be installed in the pump suction port vacuum gauge. If the control action needs to be carried out according to the suction pressure, a pressure sensor should be installed at the suction port of the pump.

3. Suction port filter. If foreign matter may enter the pump in the system and pipeline, a filter or strainer shall be installed in the suction port of the pump.

4. Separator overflow port. The excess working liquid can be discharged from the gas-liquid separator.

5. Separator liquid replenishment port. If the working fluid is insufficient, the working fluid can be properly supplemented from the rehydration port.

6. Separator level gauge. The liquid level in the separator can be observed. If automatic liquid level control is required, a liquid level gauge with signal output and an automatic overflow or replenishment device should be installed.

7. Separator pressure gauge. If pressure may be generated in the separator, a pressure gauge should be installed on the separator.

8. Thermometer. If it is necessary to observe the working fluid inlet temperature, a thermometer should be installed in the working fluid pipeline.

9. Working fluid booster pump. If the pump working fluid supply is insufficient or the working pipeline resistance is large, the working fluid booster pump can be installed.

10. Working fluid control valve. If the working fluid supply may be too large, install the control valve a in the working fluid pipeline.

11. Cavitation protection pipeline. If the suction pressure of the vacuum pump is close to the saturated vapor pressure of the working fluid, a cavitation protection line should be installed between the vacuum pump and the separator.

12, such as when used as a compressor, should be installed in the compressor between the suction and discharge pipe balance pipe and the corresponding valve accessories.

13, suction pipe, exhaust pipe, working fluid pipeline stop valve. Such as liquid ring vacuum pump, the compressor is designed to be used in parallel for multiple pumps. When sharing the separator, stop valves should be installed in the suction pipeline, exhaust pipeline and working fluid pipeline.

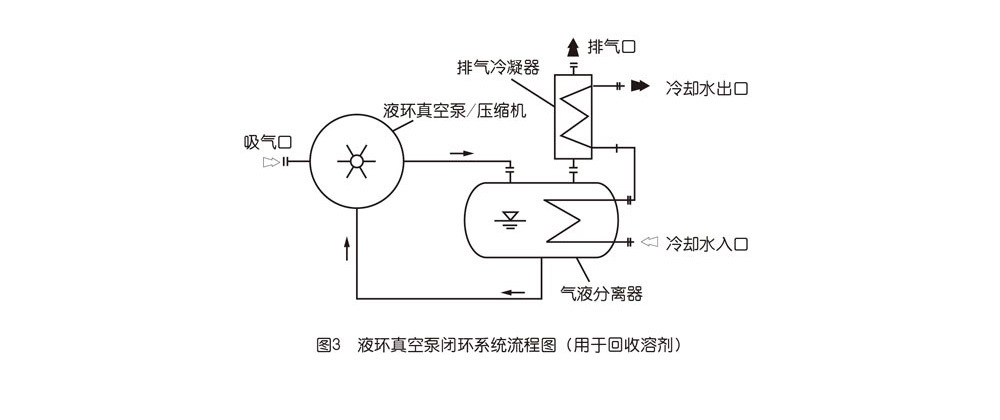

14. Exhaust condenser. If it is necessary to collect or recover the condensable gas at the exhaust port, a condenser can be installed at the exhaust port of the gas-liquid separator.

15. If there are other special requirements, the corresponding accessories can be installed.

Basic type:

1. The working fluid is water or other liquid, and the pumped medium is not recycled.

Flowchart as shown in Figure 2

2. The working fluid adopts the pumped medium, and the exhaust condenser is added to the exhaust port.

Flowchart shown in Figure 3

We have successfully applied methanol, ethanol, ethylene glycol, toluene, xylene, acetone, acrylonitrile, diazomethane, chloroform, carbon tetra-nitride and other solvents as the liquid ring vacuum pump working fluid.

Equipment selection note top:

Because the selection of liquid ring vacuum pump/compressor needs to be calculated according to the detailed working conditions, if our company needs to design and select, please be sure to provide detailed working conditions.

Previous

Previous

Leave A Message