The working principle of water ring vacuum pump

News

Release time:

2019-08-28 08:55

Summary:

Stainless steel water ring vacuum pump is a kind of rough vacuum pump, it can obtain the ultimate vacuum of 2000~4000Pa, series atmospheric ejector up to 270~670Pa. It can be used as a compressor, called a water ring compressor, which is a low-pressure compressor with a pressure range of 1~2 × 105Pa gauge pressure.

The water ring vacuum pump was originally used as a self-priming pump, and then gradually used in many industrial sectors such as petroleum, chemical, machinery, mining, light industry, medicine and food. In many processes of industrial production, such as vacuum filtration, vacuum water diversion, vacuum feeding, vacuum evaporation, vacuum concentration, vacuum moisture and vacuum degassing, etc., are widely used.

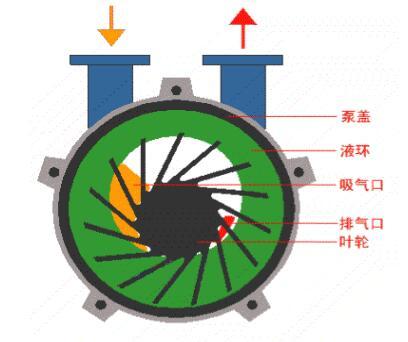

As shown in the figure: an appropriate amount of water is installed in the pump body as the working fluid. When the impeller rotates clockwise in the figure, the water is thrown around by the impeller. Due to the centrifugal force, the water forms a closed ring with similar thickness determined by the shape of the pump cavity. The inner surface of the lower part of the water ring is just tangent to the impeller hub, and the inner surface of the upper part of the water ring is just in contact with the tip of the blade (in fact, the blade has a certain insertion depth in the water ring). At this time, a crescent-shaped space is formed between the impeller hub and the water ring, and this space is divided into a number of small cavities equal to the number of blades by the impeller. If the lower part of the impeller is 0 ° as the starting point, the volume of the small cavity will increase from small to large when the impeller rotates 180 ° before, and it will communicate with the suction port on the end face. At this time, the gas will be sucked in. When the suction ends, the small cavity is isolated from the suction port. When the impeller continues to rotate, the small cavity changes from large to small, making the gas compressed; when the small cavity communicates with the exhaust port, the gas is discharged out of the pump.

Other Information

2022-03-07